Application industry

Metal Processing

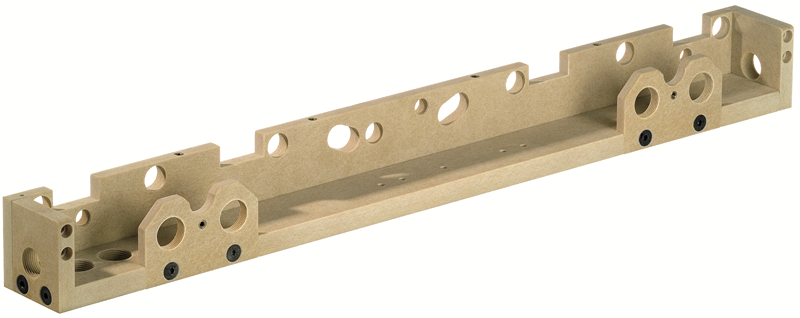

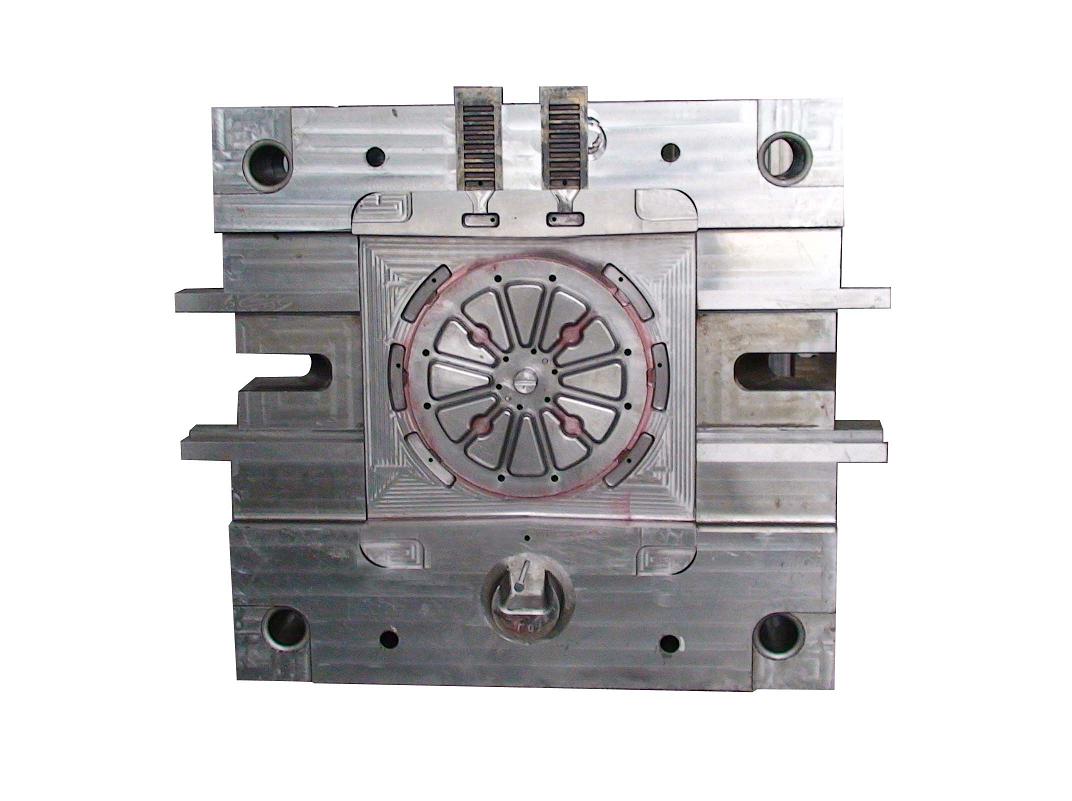

Die casting is primarily the basic process to manufacture moulded metal product, especially for magnesium or aluminum alloy processing. Similar to plastic injection molding, die casting is characterized by forcing molten metal under high pressure to a mold cavity. In a die casting process, the mould suffers repeatedly rapid temperature changes that cause interior and exterior deformation of the molding machine. The damages and toughness loss owing to temperature change (or thermal stress) may lead to micro-cracks of mold cavities, which grow gradually as they are penetrated by molten metal or damaged by continuous mechanical stresses.

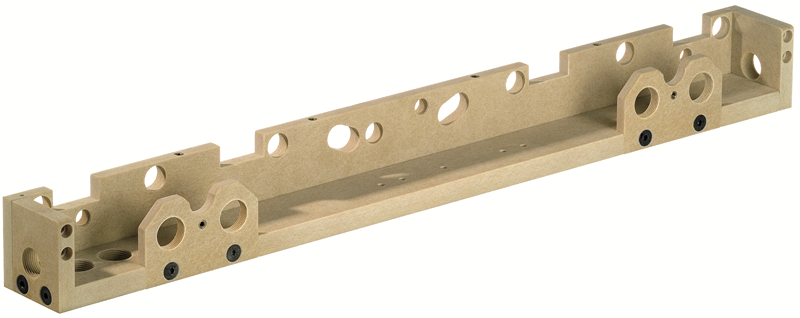

To solve those problems and improving the molding performance, thermal insulation is a fundamental consideration for die casting engineers. Keeprecision thermal insulation materials, featuring excellent insulation and mechanical properties, are beneficial to molding machines since our materials can lower the molding pre-heating time and keep the mold temperature under precise control. Therefore, we help the molding engineers minimize thermal stresses and achieve the perfect reduction of production cost.

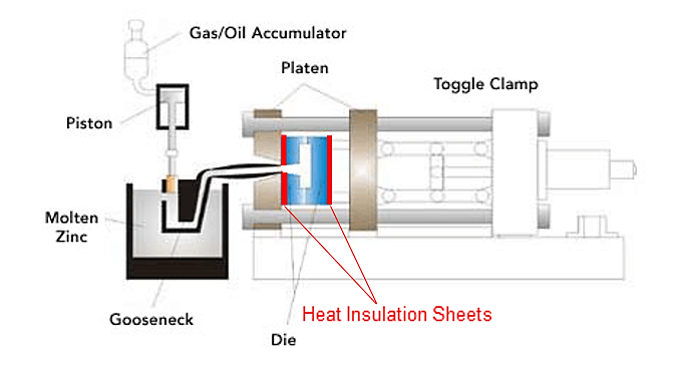

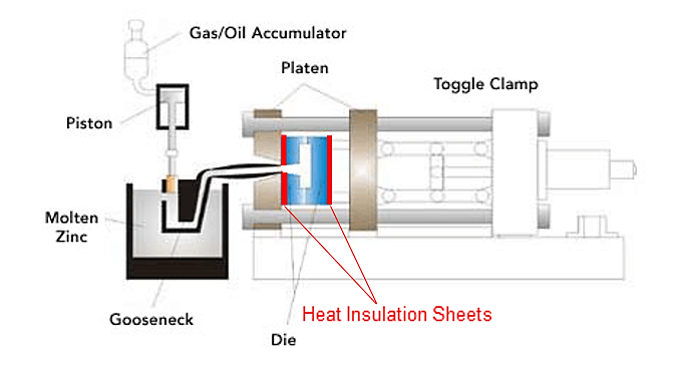

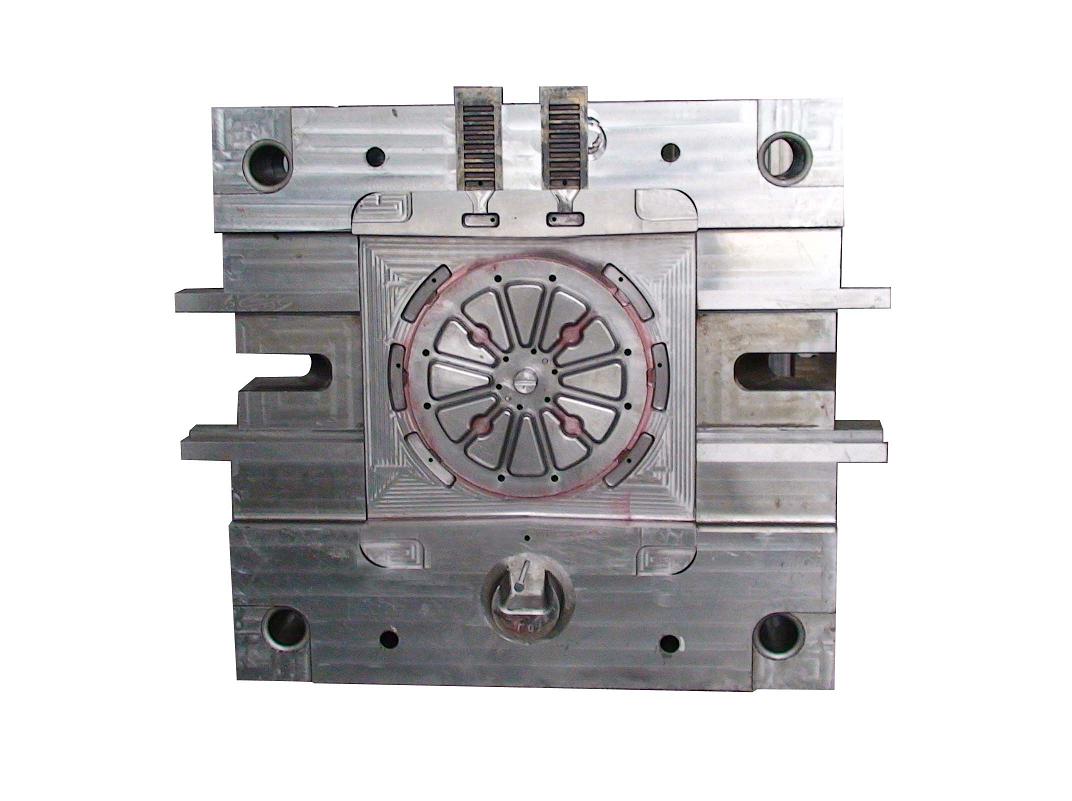

Illustration of thermal insulation in a Die Casting Machine

>> Our technicians and engineers will be happy to advise you.

Typical Application Industries

Steelworks Equipments

The electrode holders

EAF electrode beam insulation

Induction Heat Treatment

Annealing

Curing oven

Induction furnace

Casting Industry

Melting furnace

Continuous castingDie casting tool and mould

Metal Processing(Click the product name to know more about the product details)

-

- Brand name

- Long-term Temperature

- Short-term Temperature

- Thermal Conductivity

- Compressive Strength

- Flexural Strength

- Product type

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Die casting is primarily the basic process to manufacture moulded metal product, especially for magnesium or aluminum alloy processing. Similar to plastic injection molding, die casting is characterized by forcing molten metal under high pressure to a mold cavity. In a die casting process, the mould suffers repeatedly rapid temperature changes that cause interior and exterior deformation of the molding machine. The damages and toughness loss owing to temperature change (or thermal stress) may lead to micro-cracks of mold cavities, which grow gradually as they are penetrated by molten metal or damaged by continuous mechanical stresses.

To solve those problems and improving the molding performance, thermal insulation is a fundamental consideration for die casting engineers. Keeprecision thermal insulation materials, featuring excellent insulation and mechanical properties, are beneficial to molding machines since our materials can lower the molding pre-heating time and keep the mold temperature under precise control. Therefore, we help the molding engineers minimize thermal stresses and achieve the perfect reduction of production cost.

Illustration of thermal insulation in a Die Casting Machine

>> Our technicians and engineers will be happy to advise you.

Typical Application Industries

Steelworks Equipments

The electrode holders

Induction Heat Treatment

Annealing

Curing oven

Induction furnace

Casting Industry

Melting furnace

Die casting tool and mould

Metal Processing(Click the product name to know more about the product details)

-

- Brand name

- Long-term Temperature

- Short-term Temperature

- Thermal Conductivity

- Compressive Strength

- Flexural Strength

- Product type