Application industry

Plastics Processing

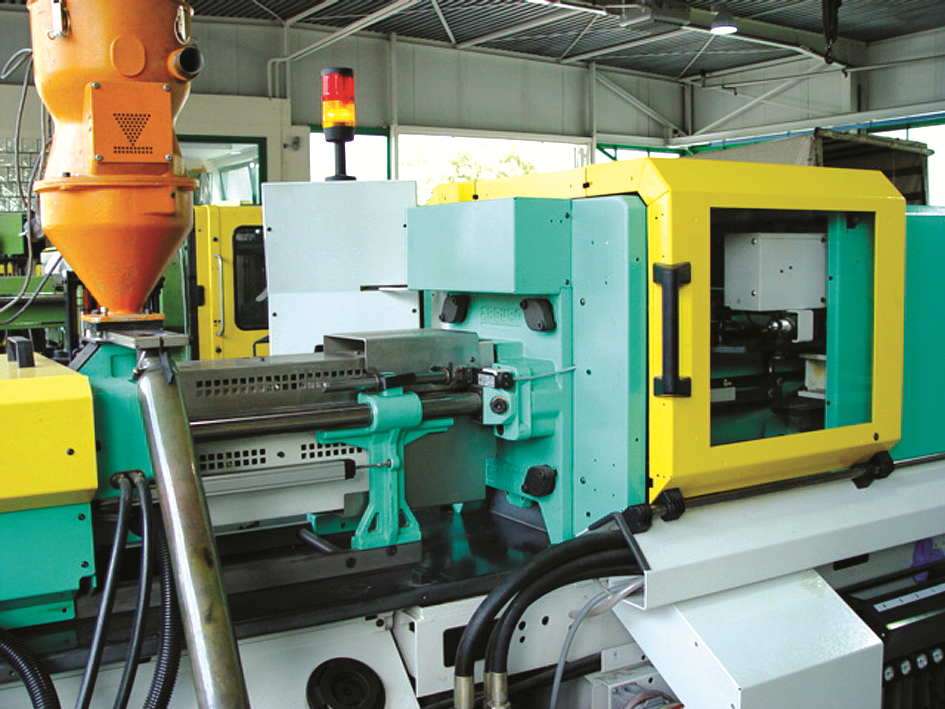

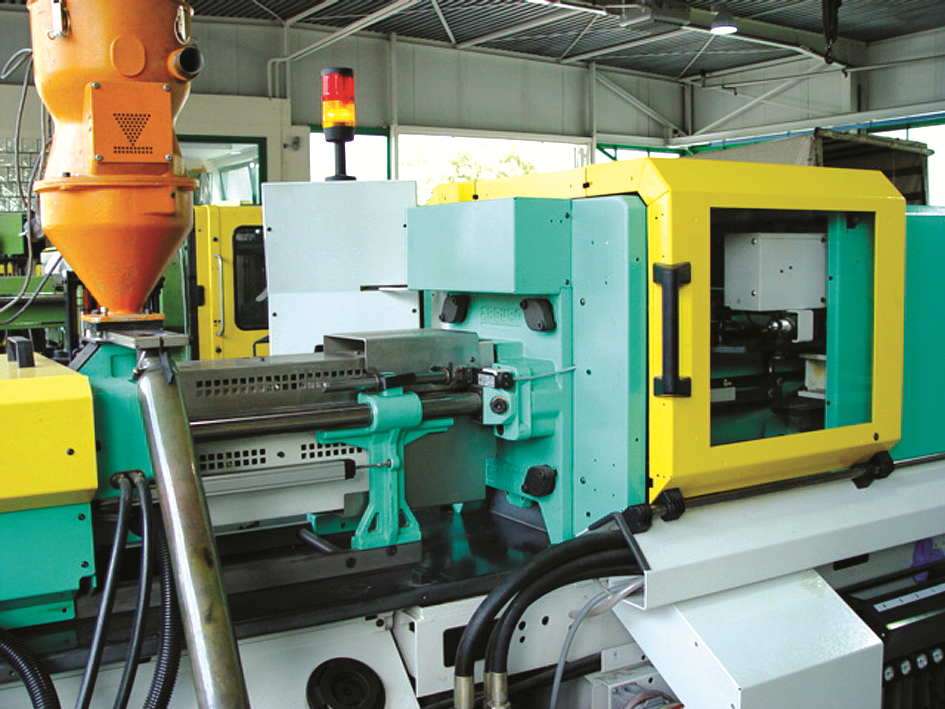

Plastics processing is the most primary industry where our thermal insulation materials are tremendously applied. Insulation for this industry is characterized by high requirements for energy efficiency, reproducible quality and cost-effectiveness. Processes like compression moulding, injection moulding, film blowing, extrusion and hot runner systems expose machines and systems to a wide variety of thermal, chemical and mechanical stresses.

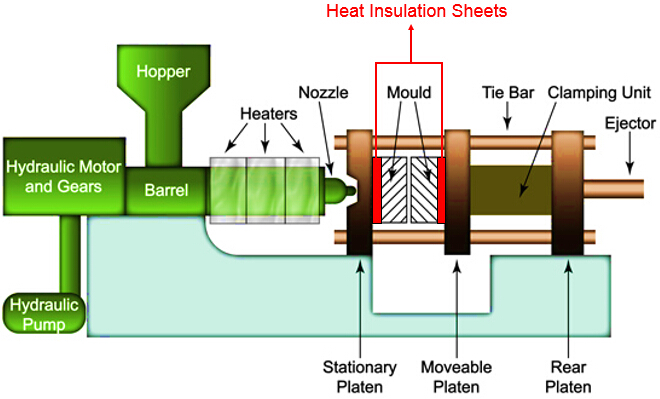

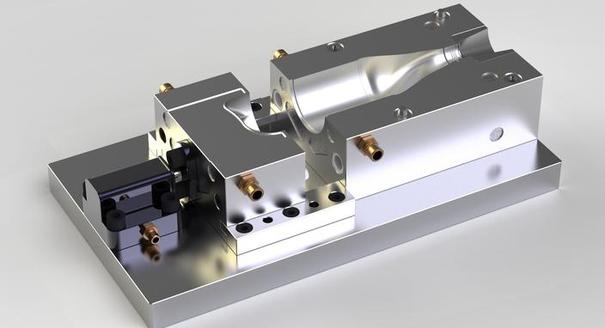

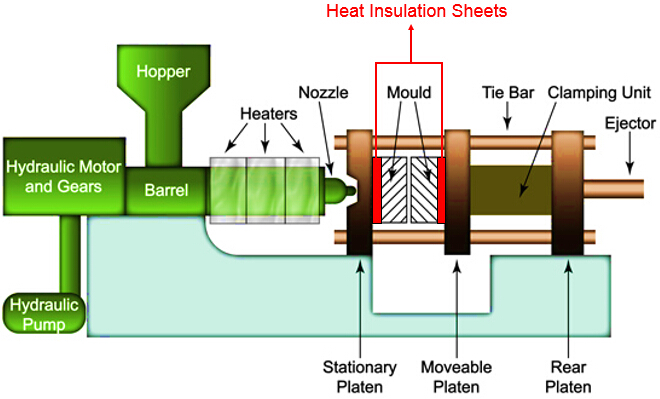

In plastic injection, for example, our products are applied on molds and dies between the top clamping plate and the stationary platen and between the bottom of the ejector housing and the movable platen. The thermal insulating properties of our sheets inhibit heat transfer from the mold to the platen, which helps conserve energy and prolong service life of machines. In the hot runner feed system, similarly, parts made from thermal insulation materials are incorporated between hot manifold and A platen, bottom clamp platen. In addition to thermal insulation, the insulation parts also support the hot manifold boards as structure members.

Thermal Insulation provided by Keeprecision avoids mechanical wear, reduces preheating time, and ensure uniform temperature distribution to improve the molding performance for our customers. Our materials have excellent thermal insulation properties, low deformability and sedimentation, great mechanical strength, and chemical inertness, which are perfectly tailored to heat insulation specifications required by the mould and tool making industry. With regards to thermal insulation applications in this industry, Keeprecision surely offers high-quality thermal insulation service to our customers' satisfactory.

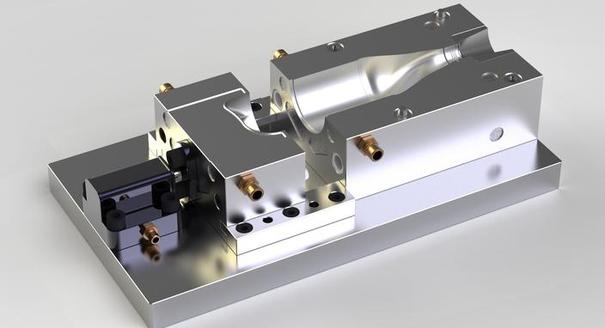

Illustration of how injection molding machines are thermally insulated

>> Our technicians and engineers will be happy to advise you.

Typical Application Industries

Mold and Tooling Industry

Molding insulation

Hot runner system

External heat insulation

Plastic Molding

Injection molding machines

Blow molding

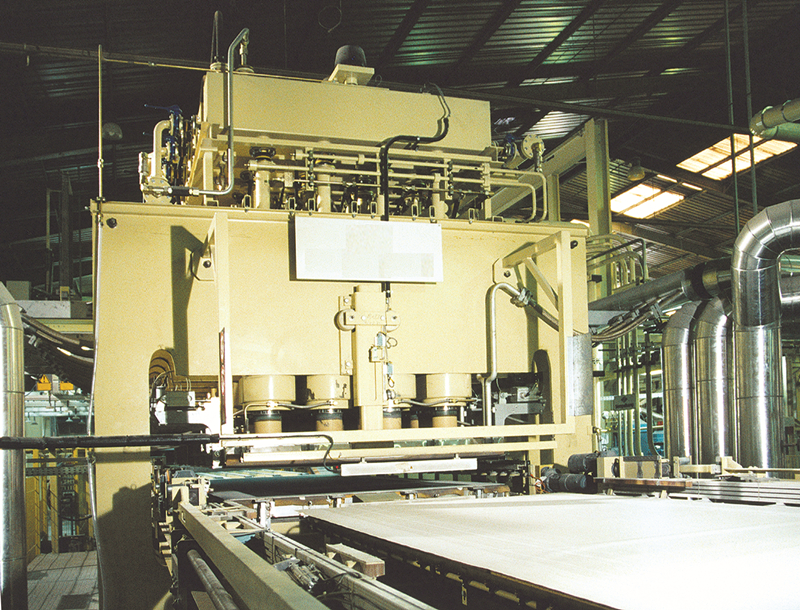

Extrusion

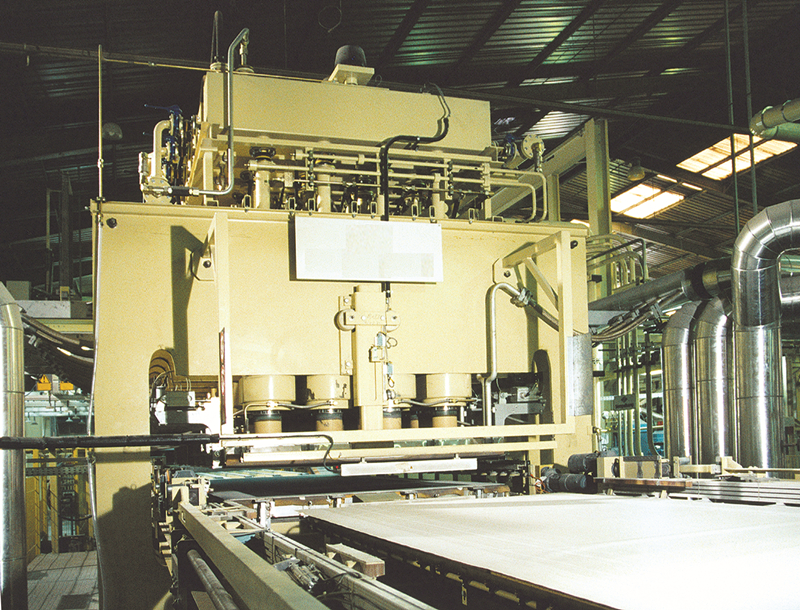

Hot-press

Thermoplastic hot press

Thermoset hot press

Packaging Machines

Packaging machinery

Embryo bottle moulds

Plastics Processing(Click the product name to know more about the product details)

-

- Brand name

- Long-term Temperature

- Short-term Temperature

- Thermal Conductivity

- Compressive Strength

- Flexural Strength

- Product type

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Plastics processing is the most primary industry where our thermal insulation materials are tremendously applied. Insulation for this industry is characterized by high requirements for energy efficiency, reproducible quality and cost-effectiveness. Processes like compression moulding, injection moulding, film blowing, extrusion and hot runner systems expose machines and systems to a wide variety of thermal, chemical and mechanical stresses.

In plastic injection, for example, our products are applied on molds and dies between the top clamping plate and the stationary platen and between the bottom of the ejector housing and the movable platen. The thermal insulating properties of our sheets inhibit heat transfer from the mold to the platen, which helps conserve energy and prolong service life of machines. In the hot runner feed system, similarly, parts made from thermal insulation materials are incorporated between hot manifold and A platen, bottom clamp platen. In addition to thermal insulation, the insulation parts also support the hot manifold boards as structure members.

Thermal Insulation provided by Keeprecision avoids mechanical wear, reduces preheating time, and ensure uniform temperature distribution to improve the molding performance for our customers. Our materials have excellent thermal insulation properties, low deformability and sedimentation, great mechanical strength, and chemical inertness, which are perfectly tailored to heat insulation specifications required by the mould and tool making industry. With regards to thermal insulation applications in this industry, Keeprecision surely offers high-quality thermal insulation service to our customers' satisfactory.

Illustration of how injection molding machines are thermally insulated

>> Our technicians and engineers will be happy to advise you.

Typical Application Industries

Mold and Tooling Industry

Molding insulation

Hot runner system

Plastic Molding

Injection molding machines

Blow molding

Extrusion

Hot-press

Thermoplastic hot press

Thermoset hot press

Packaging Machines

Packaging machinery

Embryo bottle moulds

Plastics Processing(Click the product name to know more about the product details)

-

- Brand name

- Long-term Temperature

- Short-term Temperature

- Thermal Conductivity

- Compressive Strength

- Flexural Strength

- Product type